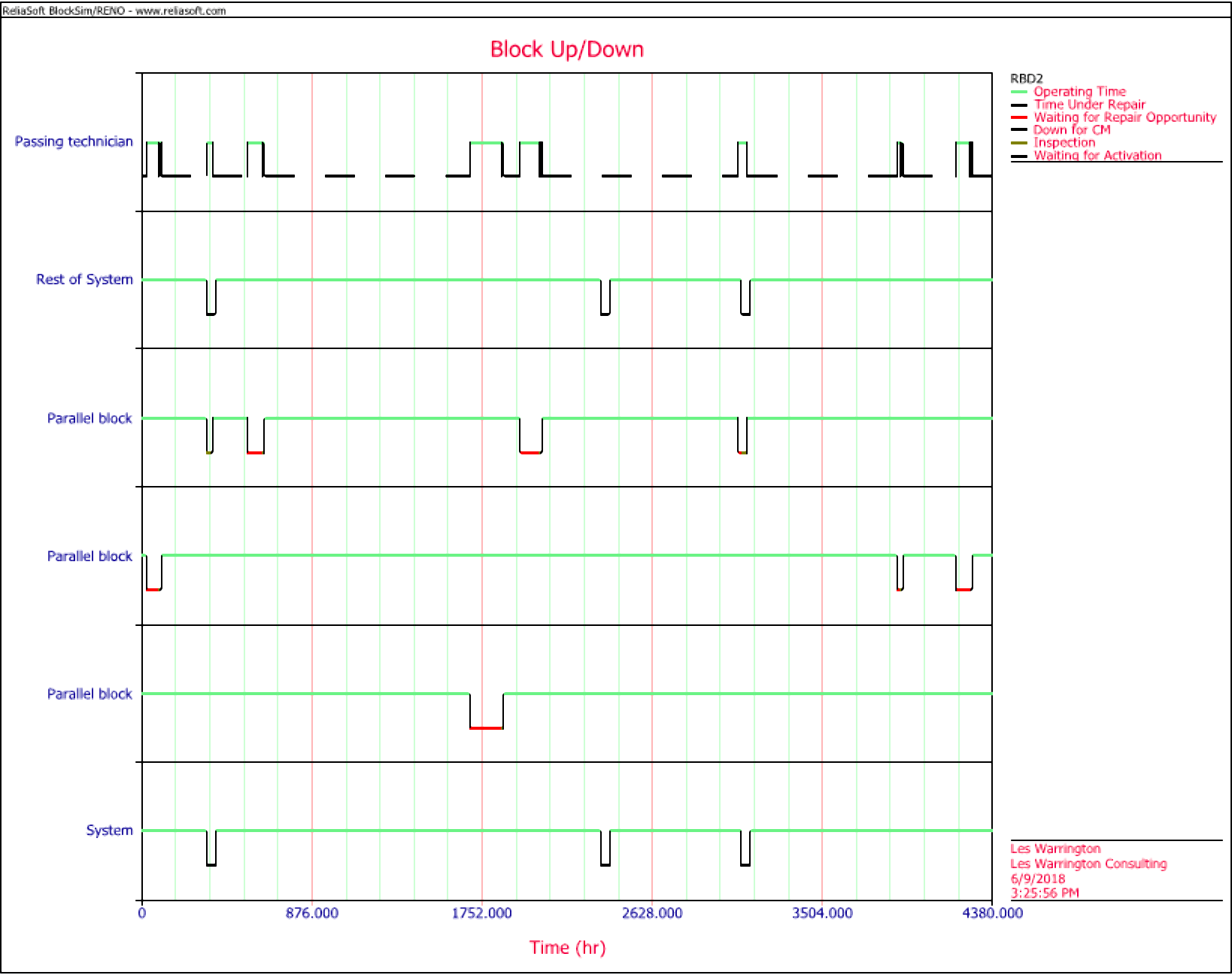

The most obvious way to improve software reliability is by improving its quality through more disciplined development efforts and test. BlockSim models system.

Generate Reference Book: may be more up-to-date Overview In life data analysis and accelerated life testing data analysis, as well as other testing activities, one of the primary objectives is to obtain a life distribution that describes the times-to-failure of a component, subassembly, assembly or system. This analysis is based on the time of successful operation or time-to-failure data of the item (component), either under use conditions or from accelerated life tests. For any life data analysis, the analyst chooses a point at which no more detailed information about the object of analysis is known or needs to be considered. At that point, the analyst treats the object of analysis as a 'black box.' The selection of this level (e.g., component, subassembly, assembly or system) determines the detail of the subsequent analysis. In system reliability analysis, one constructs a 'System' model from these component models.

In other words in system reliability analysis we are concerned with the construction of a model (life distribution) that represents the times-to-failure of the entire system based on the life distributions of the components, subassemblies and/or assemblies ('black boxes') from which it is composed, as illustrated in the figure below. To accomplish this, the relationships between components are considered and decisions about the choice of components can be made to improve or optimize the overall system reliability, maintainability and/or availability. There are many specific reasons for looking at component data to estimate the overall system reliability. One of the most important is that in many situations it is easier and less expensive to test components/subsystems rather than entire systems. Many other benefits of the system reliability analysis approach also exist and will be presented throughout this reference. Systems A system is a collection of components, subsystems and/or assemblies arranged to a specific design in order to achieve desired functions with acceptable performance and reliability. The types of components, their quantities, their qualities and the manner in which they are arranged within the system have a direct effect on the system's reliability.

The relationship between a system and its components is often misunderstood or oversimplified. For example, the following statement is not valid: All of the components in a system have a 90% reliability at a given time, thus the reliability of the system is 90% for that time. Unfortunately, poor understanding of the relationship between a system and its constituent components can result in statements like this being accepted as factual, when in reality they are false. Reliability Block Diagrams (RBDs) Block diagrams are widely used in engineering and science and exist in many different forms. They can also be used to describe the interrelation between the components and to define the system. When used in this fashion, the block diagram is then referred to as a reliability block diagram (RBD). A reliability block diagram is a graphical representation of the components of the system and how they are reliability-wise related (connected).

It should be noted that this may differ from how the components are physically connected. An RBD of a simplified computer system with a redundant fan configuration is shown below.

Ebook ekonomi pembangunan todaro economic development. He appears in Who's Who in Economics and Economists of the Twentieth Century. He lived and taught in Africa for six years.

It is possible for each block in a particular RBD to be represented by its own reliability block diagram, depending on the level of detail in question. For example, in an RBD of a car, the top level blocks could represent the major systems of the car, as illustrated in the figure below. Each of these systems could have their own RBDs in which the blocks represent the subsystems of that particular system. This could continue down through many levels of detail, all the way down to the level of the most basic components (e.g., fasteners), if so desired.

The level of granularity or detail that one chooses should be based on both the availability of data and on the lowest actionable item concept. To illustrate this concept, consider the aforementioned computer system shown earlier. When the computer manufacturer finds out that the hard drive is not as reliable as it should be and decides not to try to improve the reliability of the current hard drive but rather to get a new hard drive supplier, then the lowest actionable item is the hard drive.

The hard drive supplier will then have actionable items inside the hard drive, and so forth. Block Failure Models Having segmented a product or process into parts, the first step in evaluating the reliability of a system is to obtain life/event data concerning each component/subsystem (i.e., each block). This information will allow the reliability engineer to characterize the life distribution of each component. Data can be obtained from different sources, including: • In-house reliability tests • Accelerated life tests • Field data • Warranty data • Engineering knowledge • Similarity to prior designs • Other reference sources Additionally, component life data may also be provided by the manufacturer or supplier of the component/subsystem.